| |

IT’S NO SECRET THAT EMBA SET-UP CONTROLS FEATURE A COMPLEX PROPRIETARY

EUROPEAN DESIGN WITH COMPONENTS THAT WILL BE VERY EXPENSIVE TO

REPAIR OR REPLACE WHEN THEY INEVITABLY FAIL.

Since 1988, we have specialized in converting machine controls

for all major flexo-folders-gluers, printer-slotters or rotary

die cutters, and non-centerline machines - like the EMBAs you have

on your shop floor.

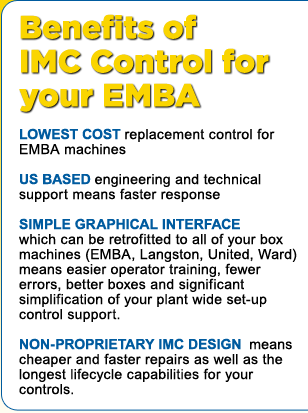

With many IMC EMBA upgrades installed and successfully running in the US today,

no one in the world sells more set-up control retrofit systems to the boxboard

industry than IMC. And, since retrofitting replacement control systems is all

we do at IMC, we are proud to offer the best replacement systems in the industry.

Our EMBA replacement control systems offer both productivity gains and reduced

maintenance costs. IMC based our EMBA control system on Open Architecture standards,

which eliminates expensive proprietary hardware. Finding replacement parts for

your upgraded EMBA system can be as easy as ordering from your local computer

store. Of course, IMC offers full replacement parts for all of our control systems

at competitive market prices.

So, not only is IMC faster and more cost-effective than dealing with EMBA direct,

our simple user interface allows for easier operator training.

IMC’s experience in replacement control systems is only half of the story. We

pair our unmatched expertise in set-up controls with an unparalleled commitment

to outstanding customer service because setup controls are our only product.

Installation is fast and easy too, with most EMBA upgrades taking just a few

days. For customers with highly active shop floors, IMC can even install over

a weekend.

|

|