Why we are the #1 supplier of

box machine set-up control system replacement retrofits

-

More set-up

control retrofits installed than

any other supplier

-

32

different OEM FFG, RDC and PS machine designs running

-

Non

proprietary / Non PLC design

-

Lowest

maintenance cost set-up control design

-

Lowest

price set-up control system on the market

-

Most

experience - set-up controls are

ALL

we do

_________________________________________________

Ignoring your set-up control problem

guarantees lost profits

Box machines can last 30 years or

more but control systems are typically obsolete in 7 years.

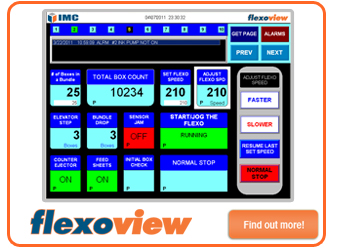

An IMC Box Pacesetter 3.0

set-up control upgrade will get you all the benefits of

the latest computerized set-up control without having to buy a new machine

and at a fraction of the price that an OEM upgrade costs.

Compared to the cost of a new press you can add a Pacesetter

for pennies on the dollar.

IMC Box should be your first

choice in productivity improvement. Other productivity

enhancing equipment such as pre-feeders, palletizers or lead

edge feeders perform only when the machine is running.

Pacesetter 3.0 makes your entire converting line more

efficient by greatly increasing your available running time.

With

over 30 years of experience

IMC

Box

is

your best solution for

ALL of your set-up control problems